Surface Plasmon Resonance

Institute of Molecular Biology and Pathology (IBPM) - Roma

Description

Surface Plasmon Resonance (SPR) is a label-free, fluidics based, real-time detection technology based on analyte binding to chemically coated sensor chips.

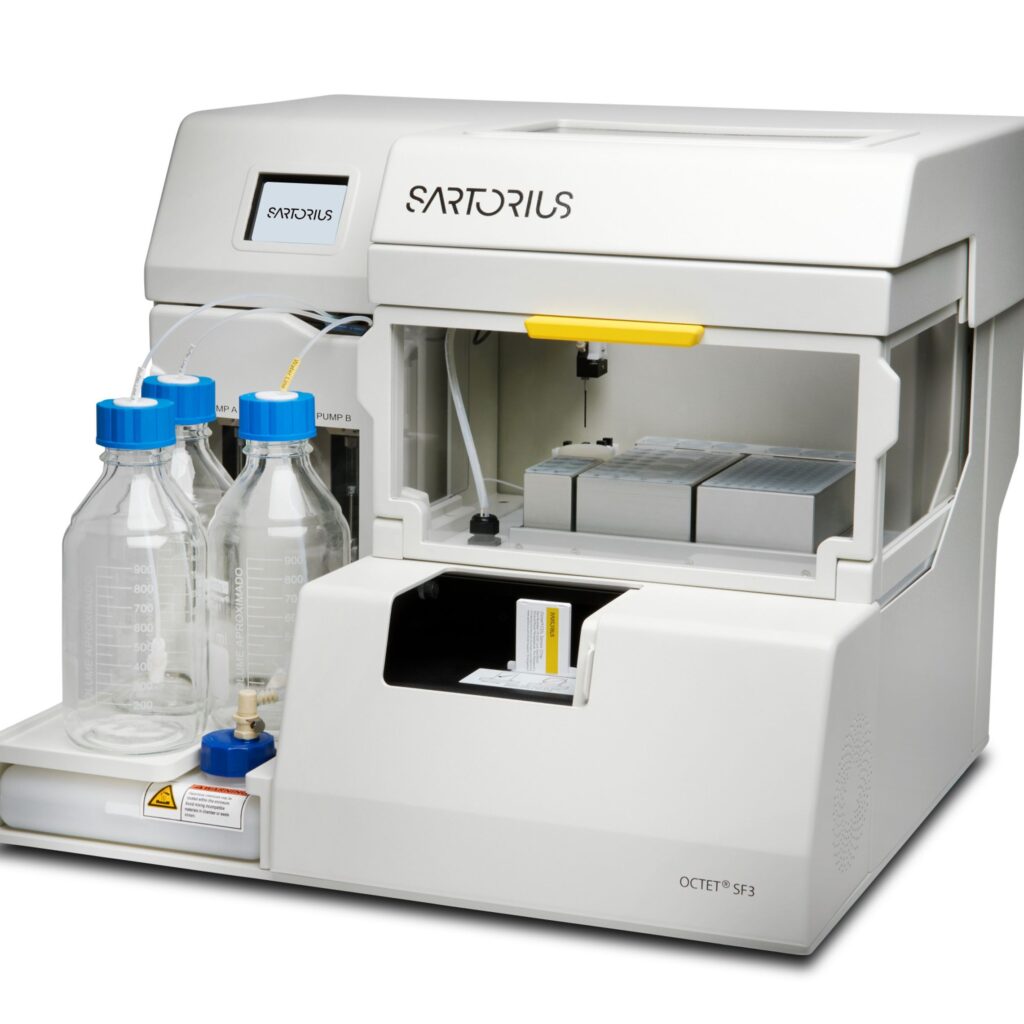

The Octet SF3 System is a fully automated, three channel, SPR-based biosensing system in a flow injection analysis configuration.

The SF3 apparatus is a Surface Plasmon Resonance benchtop molecule-molecule interaction detection system, designed for high-end functional analysis of affinity interactions, which can generate comprehensive data for up to 768 unique samples in less than 24 hours.

The SF3 system provides high quality kinetics and affinity measurements, with high assay sensitivity over a wide dynamic range. With exceptional sensitivity for both small and large molecules, low baseline noise and drift, large injection volumes and the novel OneStep® and NeXtStep™ Gradient Injection Technologies, the Octet SF3 allows users to generate high-quality kinetics and affinity data in a fraction of the time compared to standard multi-cycle kinetics SPR experiments.

Combined with software designed by users for users, the Octet SF3 offers a robust, high-throughput, low maintenance SPR solution for the rapid characterization of a wide variety of biomolecular interactions.

The Octet SF3 SPR is a unique combination of technological innovation, complemented by a robust engineering design, offering low system maintenance, high sample throughput and a highly accurate characterization of both small and large molecules.

The Octet SPR Discovery software enables rapid assay development thanks to its wizard-based methods while allowing experienced users true flexibility in assay design and optimization through custom methods and manual run modes.

To aid in optimal assay development a wide range of sensor chip surface chemistries are available.

O.U. P.I.: Andrea Ilari

People Involved: Adele Di Matteo, Gianni Colotti, Carmelinda Savino, Linda Celeste Montemiglio, Annarita Fiorillo, Giorgio Giardina, Beatrice Vallone

Application: Surface Plasmon Resonance (SPR)

The Octet SF3 system from Sartorius utilizes SPR to enable real-time, label-free analysis of a wide-range of a wide variety of biomolecular interactions, from small molecule fragments to biologics.

SPR is based on ligand and analyte binding to chemically coated sensor chips. SPR sensor chips are comprised of a thin glass slide coated with a semi-transparent gold film, protected by a rigid plastic outer cassette to shield the gold surface from direct handling. The gold surface of many Octet SPR sensor chips are coated with an additional layer of carboxymethylated dextran which allows covalent modification of the surface using a range of chemistries, including amine and thiol. This allows the user to immobilize and study a wide variety of molecules such as proteins, antibodies, nucleic acids and small molecules, in order to generate kinetic, affinity, concentration and binding specificity data in real-time.

The sensor chips can be classified according to a number of variables, such as their immobilization matrix (2D or 3D), their binding capacity (low, medium or high), or the type of bond formed with the ligand (covalent or affinity capture).

The Octet SF3 System is a Surface Plasmon Resonance benchtop molecule-molecule interaction detection system which can generate comprehensive data for up to 768 unique samples in less than 24 hours.

Key advantages of the Octet SF3 System include:

– Determine accurate kinetics and affinity using the unique OneStep Gradient Injection which eliminates the need for multiple analyte concentrations, reduces surface regeneration injections and significantly reduces assay development time.

– High sensitivity sample measurement for both small and large molecule assays.

– High precision over a broad range of kinetic rate constants allows the measurement of even the highest affinity interactions with confidence.

– NeXtStep Gradient Injections for highly accurate competition assays

Unique design/performance specifications that are essential for the Octet SF3 Systems are:

1. OneStep® Gradient Injection Technology: based on the Taylor dispersion theory, OneStep Gradient Injections diffuse a single concentration of analyte into a moving stream of buffer to create an analyte concentration gradient of at least 3 orders of magnitude, allowing an accurate measurement of molecule kinetics (ka and kd) and affinity (KD) using a sigmoidal gradient injection. While standard Multi-Cycle Kinetics (MCK) can also be performed on the Octet SF3, OneStep Injections eliminate the need to prepare a dilution series of each analyte.

OneStep Gradient Injection advantages include:

– Accuracy: negligible rate constant differences with multicycle kinetics.

– Speed: significantly less time required for sensor chip regeneration, sample preparation, acquisition, and analysis to obtain kinetics and affinity.

– Throughput: unlock the full potential of each sample plate as only a single analyte concentration is required to assess each interaction.

2. OneStep® Gradient High-Throughput Injection Technology: the system incorporates a high throughput mode which can analyze 768 analytes for kinetic and affinity measurements within 24 hours using a 1 analyte, 1 injection approach.

3. OneStep® Two Comp Injection Technology: determines changes in analyte kinetics and binding under different conditions by injecting modified running buffer solutions from a 96 or 384 well plate, as opposed to from the main running buffer source, to change the environment of the flow cell immediately prior to analyte injection.

4. OneStep® Pulse Injection Technology: determines the analyte diffusion coefficient (D) following a diffusion-based gradient injection response. High analyte concentrations will bind independently to the sensor surface, while low concentrations will bind in a dependent manner.

5. NeXtStepTM Gradient Injection Technology: high-throughput competitive injection directly from a 96 or 384 well plate to enable competition analysis of multiple samples.

Competition assays are very useful in drug discovery, yielding the ability to find active site binders by competing fragment hits with a control molecule. The NeXtStep Injection Technology has the ability to determine the behavior of an analyte in the presence of a competitor molecule from a single injection. Since the competitor does not need to be present in the running buffer, NeXtStep allows to assess multiple analytes and competitors in a single assay. Full kinetic profiles, affinity and site-specific competition can be clearly identified as a modulation of binding in the presence of the competitor molecule. NeXtStep Gradient Injections comprise of solutions A (analyte and competitor molecule) and B (competitor molecule only), with the competitor molecule concentration kept constant throughout. Both solutions are sequentially diffused into the sample holding line, where upon reaching the flow cell, the order of the solutions is reversed. The first part of the injection consists almost entirely of solution B. As the NeXtStep Injection progresses and the concentration of the competitor molecule remains constant, the analyte concentration increases in a gradient fashion.

6. Octet SPR Discovery Software: includes a hit selection feature for the normalization, merging and analysis of fragment or other screening data sets to accurately select hits. The Octet SPR Discovery software allows one to rapidly define sample parameters, create common or independent sample flow rates, add injection volumes and report points. The method setup page allows the user to select from numerous pre-written methods that help guide setup and provides the flexibility to write, modify, and view bespoke methods.

Rapid Data Analysis: the Octet SPR Analysis software uses a unified approach for the selection of hits from nonhits and allows normalizing of screening data across different days and instruments, so an entire screen campaign can be compared rapidly. This integration results in a major reduction in post-processing time. The software provides models incorporating kinetics, affinity, mass transport corrections, and multi-site binding as required to fit the interaction.

Primary screening data are ready for KD analysis without having to perform a laborious, time consuming, and potentially error-prone secondary screening.

Maintenance: maintenance of the Octet SF3 requires minimal user interaction, with less time spent on maintaining the system and more time focussed on generating data.

7. Sample and Reagent Rack Flexibility: can test up to two (2) plates (96 or 384 well) plus fourteen (14) additional reagent vials in a single unattended run.

8. System wetted materials: robust and chemically resistant to withstand injections with harsh materials, such as 100% DMSO, >50% Acetonitle, approximately 4% Sodium hypochlorite (common bleach), 6-8 M Guanidine HCl or Urea, etc.

9. Injection flow path options – system utilizes three (3) flow channels linked in series with injection flow path options of: FC1 only, FC1-FC2 only, FC1-FC2-FC3, FC3 only, FC3-FC2 only, or FC3-FC2-FC1.